Norman T300

+5

oldgit

donp

maryalice

mattblack

StuartTurnerSteve

9 posters

Page 2 of 4

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: Norman T300

Re: Norman T300

blue cat wrote:Good news, I found this in the spares box:

Cool. Are you confident that that is right for my engine?

I've not even had a chance to take a proper look at mine yet: it's been too low to the ground ,too heavy to lift, and I've had nothing sensible to lift it onto...

But I'm here now, and so it it, and I'm just putting off unpacking the car...

A set of alloy welding rods also arrived this morning, I shall have a play with those, I think, but the prospect of a spare part if it all goes horribly wrong will give me some confidence to have a go...

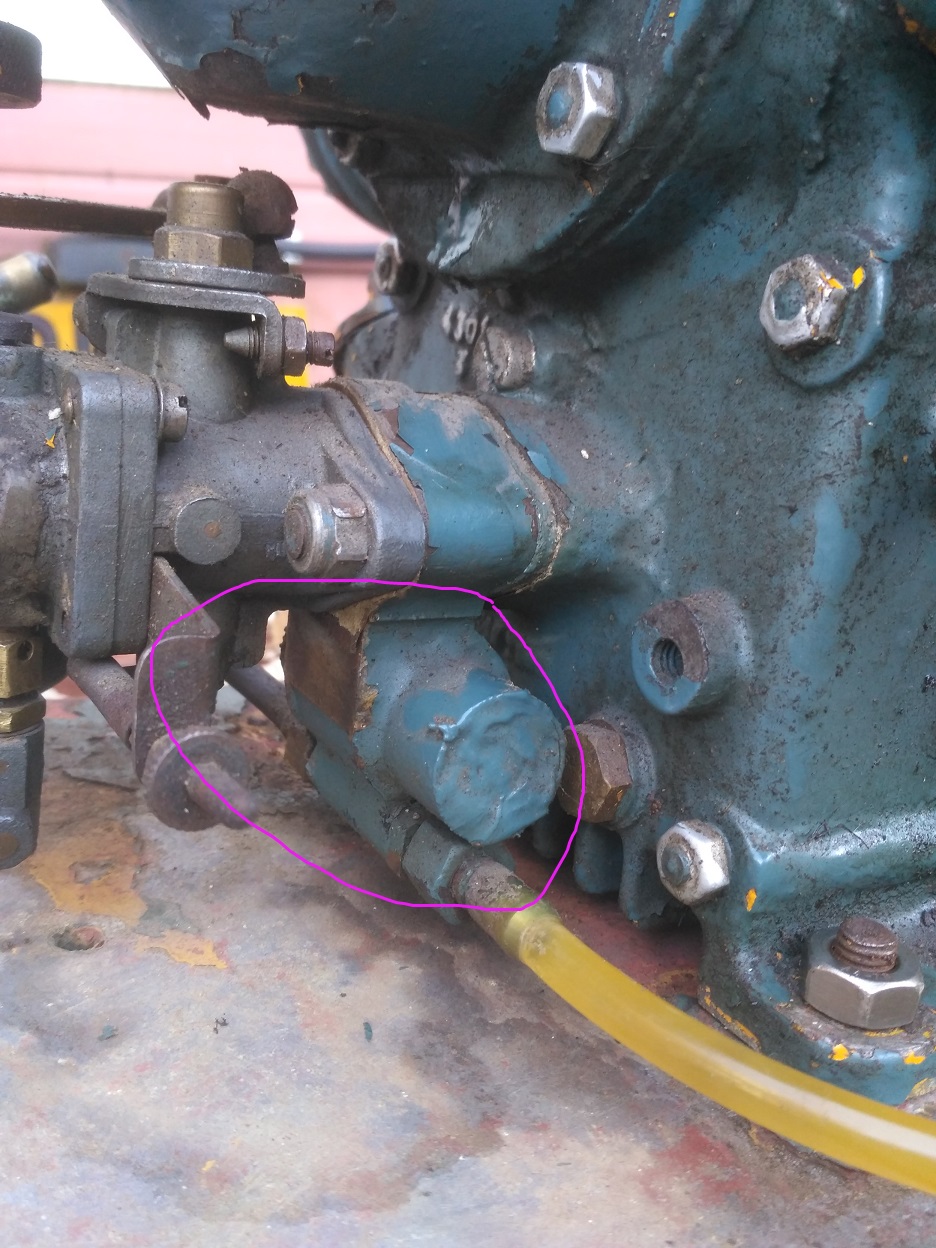

Bad news, it is not drilled for a tickler button (white cricle):

Is that a big problem, or simply a matter of a bit of careful drilling?

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

Yes, it will fit your engine, part number is 26FHG which should be the same number as the part on your engine.

Carefull drilling using the original as a guide.

Have fun with the alloy rods.

Carefull drilling using the original as a guide.

Have fun with the alloy rods.

_________________

blue cat

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Re: Norman T300

Re: Norman T300

blue cat wrote:Yes, it will fit your engine, part number is 26FHG which should be the same number as the part on your engine.

Carefull drilling using the original as a guide.

Have fun with the alloy rods.

Initial experiments with the alloy rods don't seem promising. These were the cheap rods, and not the magical "second generation" ones.

Besides which, I was struck by a rare bout of common sense: there's a part available, why not use it?

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

I weighted the dynamo. Somewhere over 45kg. The engine is about 27.

I cannot find any numbers or information of any sort anywhere on it.

That thing at the back is presumably some kind of greasing point. It's certainly full of grease.

Not a type I've come across: do you just ram the cap full of grease and wind it on?

The question now is of what to do with it.

The obvious answer is to bolt it back onto the Norman, but that makes the rig too heavy to move, and I don't actually have any use for 35V.

I suppose I could get a couple of batteries and a 24V inverter. There was a chap at Dorset selling them at a very reasonable price and I nearly bought one...

I cannot find any numbers or information of any sort anywhere on it.

That thing at the back is presumably some kind of greasing point. It's certainly full of grease.

Not a type I've come across: do you just ram the cap full of grease and wind it on?

The question now is of what to do with it.

The obvious answer is to bolt it back onto the Norman, but that makes the rig too heavy to move, and I don't actually have any use for 35V.

I suppose I could get a couple of batteries and a 24V inverter. There was a chap at Dorset selling them at a very reasonable price and I nearly bought one...

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

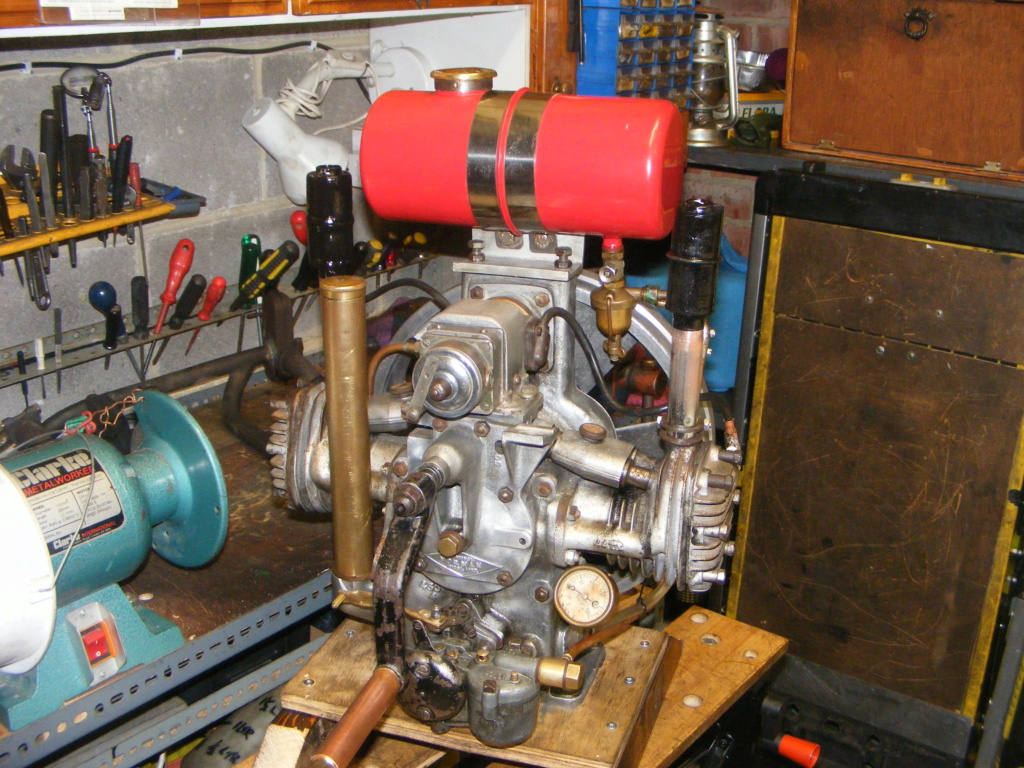

You got a very rare piece there !!!, very few examples of this on preserved Norman engines.

It's a fuel warmer/heater. The exhaust pipe passes through the centre part.

It's a fuel warmer/heater. The exhaust pipe passes through the centre part.

_________________

blue cat

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Re: Norman T300

Re: Norman T300

Best that I don't butcher it then.blue cat wrote:You got a very rare piece there !!!, very few examples of this on preserved Norman engines.

The exhaust pipe passes through the centre part.

I'm fairly sure that it doesn't: my exhaust ports just stick up in the fresh air...

Sorry, that's not the best picture, it was the one I had to hand.

Is there some way to edit after uploading? I can't see one.

So, presuming that the exhaust should run through there, I shall have to look at how to re-instate it when I build the new pipes.

The only pattern I've got to work from is the picture on page one.

From that, I'm guessing that it's only one pipe runs through there, before it joins the other to go through a common silencer.

What's the established opinion on making exhausts out of copper?

It bends rather more easily than steel...

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

I've seen copper exhausts on small engines.

Maryalice

Maryalice

maryalice- Life Member

- Posts : 1235

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Re: Norman T300

Re: Norman T300

Hairyloon wrote:Best that I don't butcher it then.blue cat wrote:You got a very rare piece there !!!, very few examples of this on preserved Norman engines.The exhaust pipe passes through the centre part.

I'm fairly sure that it doesn't: my exhaust ports just stick up in the fresh air...

So, presuming that the exhaust should run through there, I shall have to look at how to re-instate it when I build the new pipes.

The only pattern I've got to work from is the picture on page one.

From that, I'm guessing that it's only one pipe runs through there, before it joins the other to go through a common silencer.

Yes, only the left hand exhaust pipe goes through there.

Stock photo showing general disposition of exhaust pipes. As you can (not

_________________

blue cat

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Re: Norman T300

Re: Norman T300

I think that: the exhaust heat to the intake pipe, will be to prevent icing. It may be that these power units were usually in a cowling or housing. If some were used in an exposed state; it is very likely that ice would form in the intake and strangle the engine.

When I was an apprentice, (yeah, I know, the old 'when I was a boy' routine), our garage had a 4 cyl, side valve Coventry powered generator; to keep the petrol pumps working during power cuts. This unit had been removed from it's housing in a 4 wheeled trailer (ex search light unit), and installed in a corner of a car showroom. It was run up periodically to make sure we could rely on it if needed.

The only times that it was called on to really do it's job was if there was a power cut; which was mostly when there was a thunderstorm. After a few minutes running the engine would reduce power an eventually stop. By the time the pump attendants had alerted you and you went to the unit: all was well, you just started it up and all was fine, for a few minutes, but then again after a few minutes it would again 'peter out'. After a time it was realised that the humidity in the air was forming ice around the carburettor and manifold.

On this unit the radiator fan pulled air from the engine side and blew it through the radiator; presumably so as not to blow hot air onto the generator. While this would work satisfactorily in it's original housing; it meant the the induction system was starved of heat when the engine was exposed.

oldgit- A true Stationary engine owner

- Posts : 151

Join date : 2019-07-07

Re: Norman T300

Re: Norman T300

Well, the new carburettor top is on and the engine is back together with the added benefit of an air filter, but it's not running terribly well: a definite tendency to backfire.

Any tips for tuning it?

As far as I can see there is only one screw to adjust...

I may have to take drastic action and look for the manual: I know I have one here some where...

Also, do we have any clues to what speed it should be running at? I don't get many volts out of the dynamo unless I rev it quite high... Though I haven't got that set up properly yet, not least because I am only guessing at how to do it. I'm wondering if it wants a battery to energise the field coils, but I would expect it to energise itself from the residual magnetism, which it must be doing because it does generate volts...

Any tips for tuning it?

As far as I can see there is only one screw to adjust...

I may have to take drastic action and look for the manual: I know I have one here some where...

Also, do we have any clues to what speed it should be running at? I don't get many volts out of the dynamo unless I rev it quite high... Though I haven't got that set up properly yet, not least because I am only guessing at how to do it. I'm wondering if it wants a battery to energise the field coils, but I would expect it to energise itself from the residual magnetism, which it must be doing because it does generate volts...

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

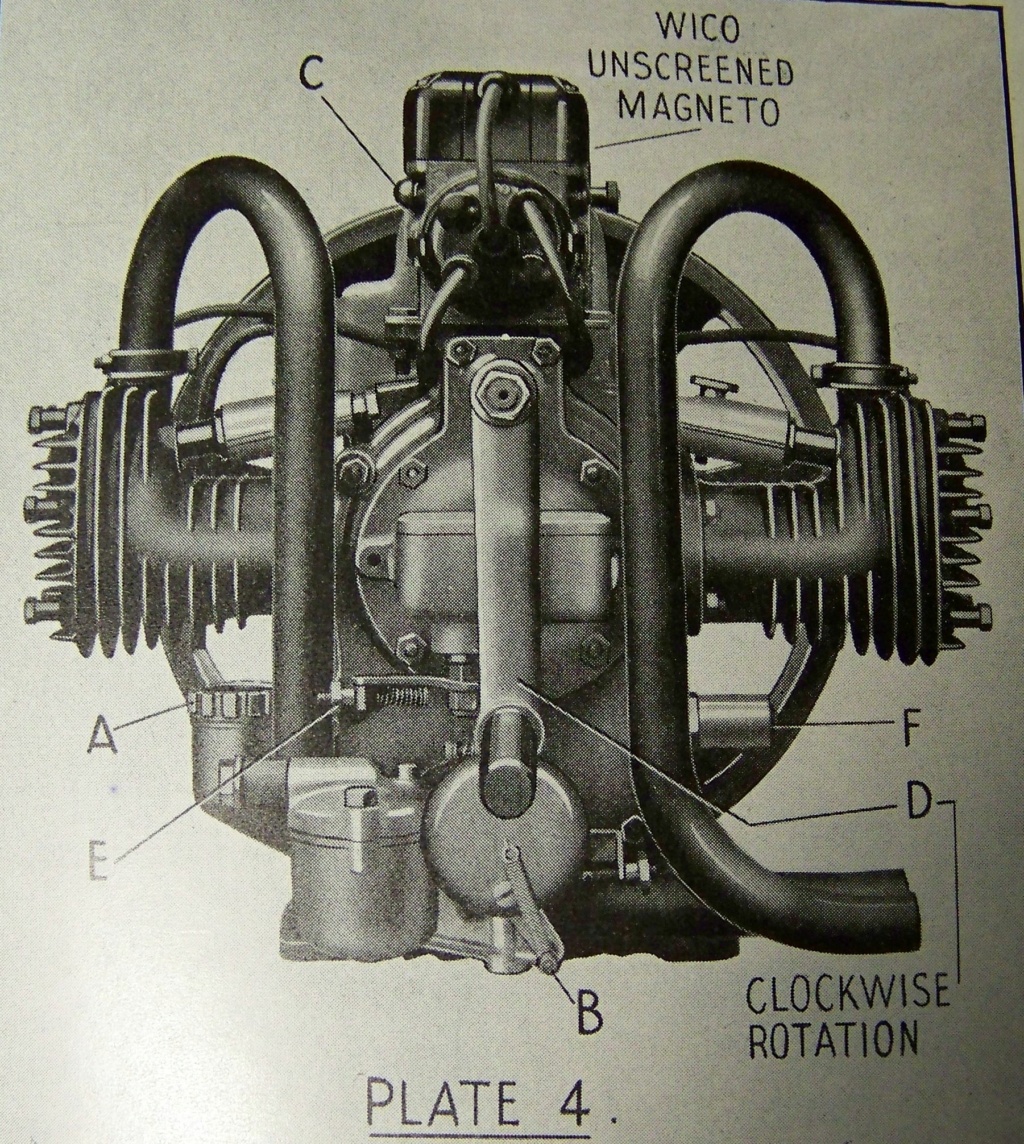

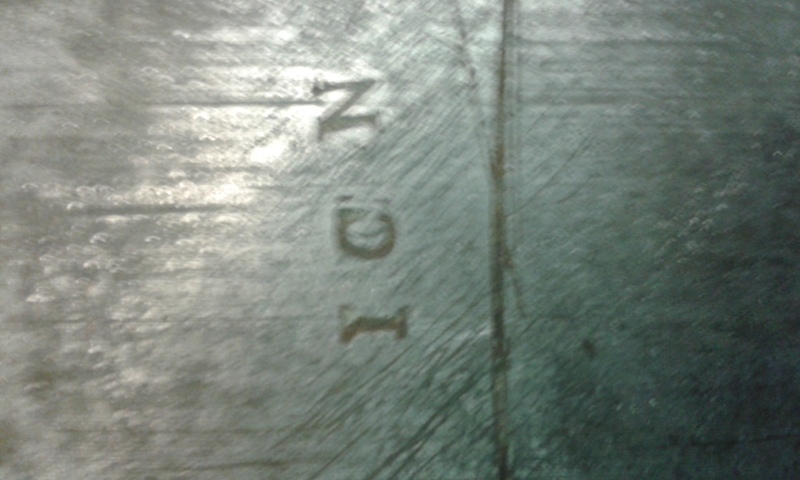

If it's backfiring check that the timing is correct, with the BTH mag on a Mk1 the points should just open when it says IGN on the flywheel it at the top.

Standard running speed is 1500-1800 depending on the set up.

Standard running speed is 1500-1800 depending on the set up.

_________________

blue cat

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Re: Norman T300

Re: Norman T300

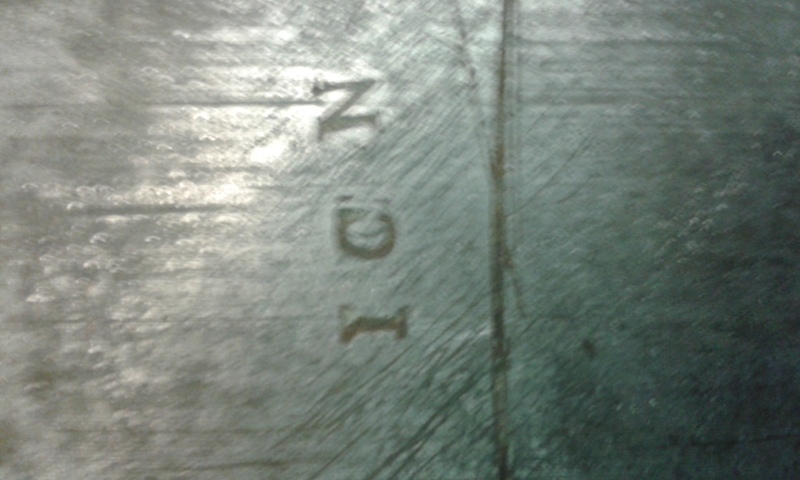

I'm not convinced that it says "IGN", at least not anywhere I can spot it from this angle. The mark is fairly clear, with an arrow, a bit before TDC, where I would expect it, so I think it is the right one.blue cat wrote:If it's backfiring check that the timing is correct, with the BTH mag on a Mk1 the points should just open when it says IGN on the flywheel it at the top.

Looks like the timing is well out, but it's not clear how to adjust it. I'm going to take drastic measures and RTFB.

ETA: Well that didn't help a whole lot. I shall have another look...

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

Have a look at my thread - page 2

https://ukengineforum.forumotion.com/t9440-another-norman-t300?highlight=another+t300

Note typos

https://ukengineforum.forumotion.com/t9440-another-norman-t300?highlight=another+t300

Note typos

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2691

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Norman T300

Re: Norman T300

Well I've moved it around a bit, and I've had no backfiring since, but I can't get it to run sensibly.Hairyloon wrote:ETA: Well that didn't help a whole lot. I shall have another look...

I've got no means of measuring it, but when set to "run", it was screaming and putting out 60V+, so I reckoned that was too fast and wound it back quite a lot. Now on run, it'll only run on full choke...blue cat wrote:Standard running speed is 1500-1800 depending on the set up.

And I ran out of petrol.

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

[quote="Hairyloon"]

Well if you are getting +60V out of a 35V generator, and the engine is screaming, then yeah it's probably going just a little too fast.

You need to have a real serious look at the arrangement of the linkages between the governor and the throttle.

Hairyloon wrote:

I've got no means of measuring it, but when set to "run", it was screaming and putting out 60V+, so I reckoned that was too fast and wound it back quite a lot. Now on run, it'll only run on full choke...

And I ran out of petrol.

Well if you are getting +60V out of a 35V generator, and the engine is screaming, then yeah it's probably going just a little too fast.

You need to have a real serious look at the arrangement of the linkages between the governor and the throttle.

_________________

blue cat

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Re: Norman T300

Re: Norman T300

Just checking that we are sure it is a 35V generator: this one looks quite similar and claims to be 110VDC.blue cat wrote:Well if you are getting +60V out of a 35V generator, and the engine is screaming, then yeah it's probably going just a little too fast.

I'm fairly confident that we are right, this is just a little niggle.

My current assessment was that the adjuster wheel was wound in far too far. I've wound it out and it seems a more sensible speed, except it won't run stably (yet).You need to have a real serious look at the arrangement of the linkages between the governor and the throttle.

I'm guessing that the previous owner didn't read the instructions and thought (as I did) that the knob was to set the speed, rather than being a two position thing to change between run and slow run.

Or maybe they were trying to adjust it to run with the air filter missing?

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

Woodsman wrote:Have a look at my thread - page 2

https://ukengineforum.forumotion.com/t9440-another-norman-t300?highlight=another+t300

Hmm. That thread appears to say there is no adjustment: everything is keyed together. My findings concur...

Apart from the gap in the points: if that's too wide, it may open too soon... I've closed it a bit and it's come closer. Not found my feeler guages yet to do it properly.

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

Woodsman wrote:Huge thanks to Mark (Sparkieb) for setting me on the path of righteousness.

So everything involved in ignition timing is keyed (see previous) except for the drive coupling itself which is a taper fit held by a set screw. What a faff!

So not all keyed. Have you checked for TDC and IGN marks on the flywheel?

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2691

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Norman T300

Re: Norman T300

Woodsman wrote:Woodsman wrote:Huge thanks to Mark (Sparkieb) for setting me on the path of righteousness.

So everything involved in ignition timing is keyed (see previous) except for the drive coupling itself which is a taper fit held by a set screw. What a faff!

So not all keyed.

No, but there seemed to be a consensus that that coupling ought not need to be messed with.

Have you checked for TDC and IGN marks on the flywheel?

I've got the marks: that's how I know it's early. It's just not marked "IGN".

Picture shows the position it was firing at, according to the strobe. Is a bit closer now, I think, but still a smidgin ahead.

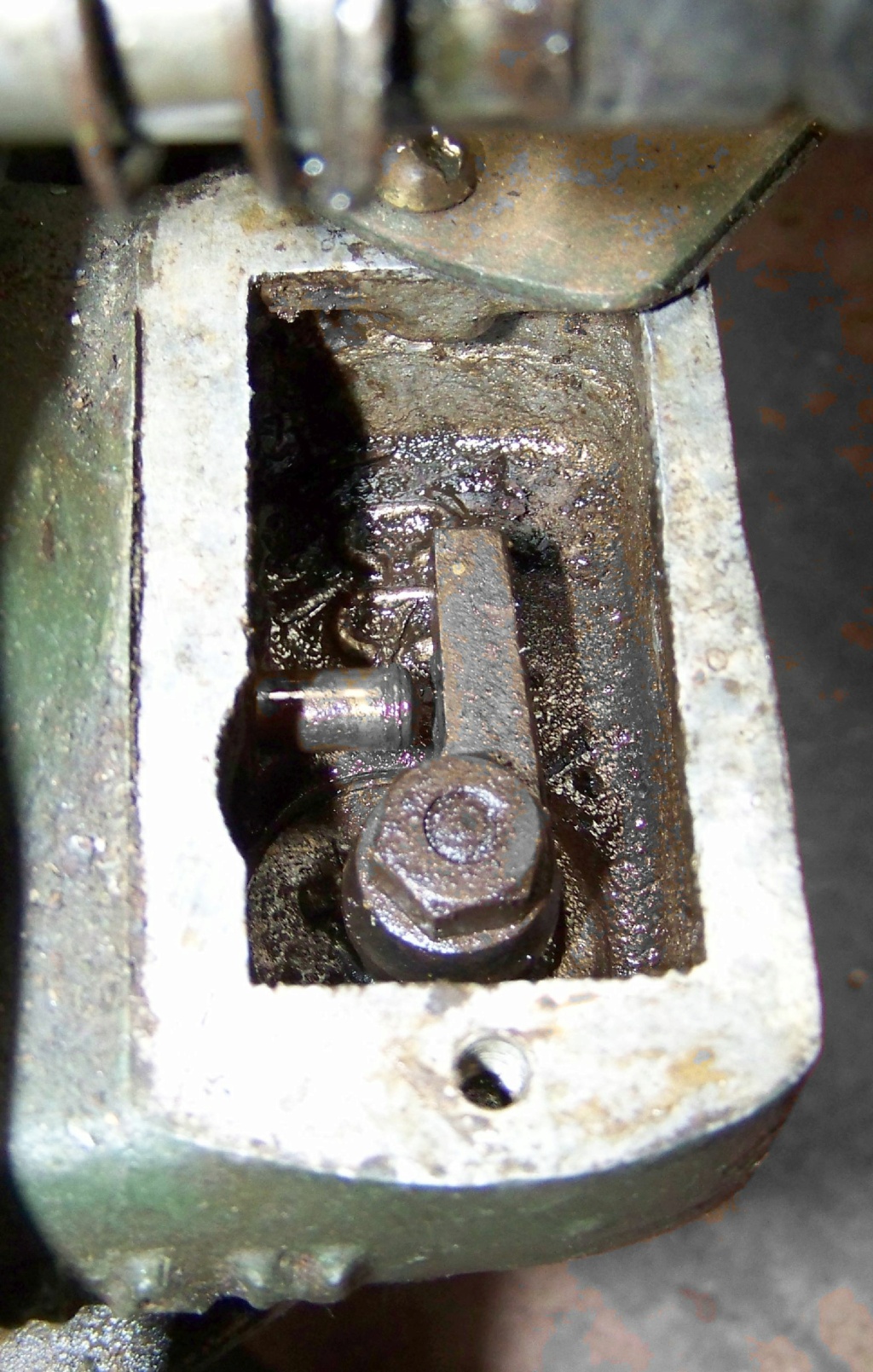

blue cat wrote:You need to have a real serious look at the arrangement of the linkages between the governor and the throttle.

Well, I'm not sure what they're supposed to look like, but they look like this, showing it at idle and at run:

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Re: Norman T300

Re: Norman T300

blue cat wrote:I'll come back to you on that after the weekend.

Thank you. I may have another play tomorrow, try to at least give some coherent report about how it is behaving.

Hairyloon- A true Stationary engine owner

- Posts : 117

Join date : 2014-03-27

Re: Norman T300

Re: Norman T300

This is an exposed Norman T300/T600 governor.

Here it is at rest.

The brass weights are at the top of the photo and the governor rod is at the bottom. This is normally hidden inside the governor bell housing, and you can only see the governor rod by removing the nameplate.

When the engine is running the brass weights will move outwards, I have simulated this with two screwdrivers..

As you can see, the governor rod moves inwards by about half its length, which catches a few people out.

The normal position of the variable parts of the throttle are shown here.

I think that these parts on your engine are in the correct position. You can alter the position of these two parts to give different engine speeds.

When the knurled wheel speed control is turned fully clockwise the governor rod should be touching the governor finger.

In this position the throttle levers move inwards and the throttle is fully open.

As the engine speed increases, the governor rod will move inwards, causing the throttle levers to move outwards which should then close the throttle to a position set by the variable parts of the throttle noted previously.

When the knurled wheel speed control is rotated fully anticlockwise the governor rod is not in contact with the governor finger.

At this position the governor is not connected to the throttle levers and has no influence on them. The throttle levers should position the throttle plate in an almost closed position to give a much reduced engine speed.

There is also a small amount of speed adjustment with the very small knurled knob within the throttle lever assembly itself.

I have also assumed that you have a return spring attached to the bottom part of the throttle spindle underneath the carburettor.

_________________

blue cat

blue cat- Life Member

- Posts : 1044

Join date : 2013-10-10

Page 2 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Page 2 of 4

Permissions in this forum:

You cannot reply to topics in this forum|

|

|